Vacuum cooking

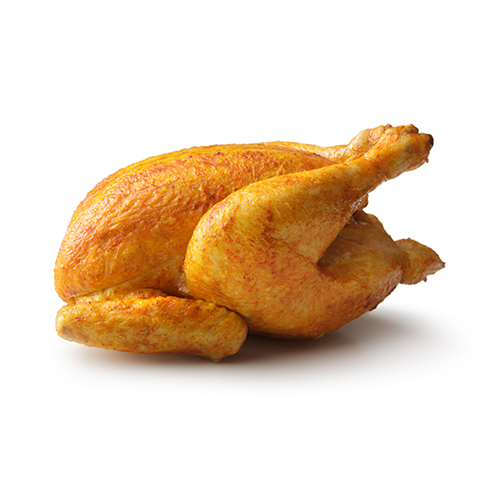

The use of vacuum as a cooking technique enhance the flavours and aromas of the food without dispersing the vitamins and mineral salts, reduces the weight loss of the product thanks to non-evaporation of the water in the food and finally, with the use of low temperature steam, tenderer food is obtained. The use of delicate steam prevents the proliferation of all those heat-resistant bacteria that may be present in sleeping form in foods placed under vacuum. The use of a core probe, especially in the case of cooking of meat or fish, is recommended to ensure the degree of optimal temperature and to obtain the best hygienic and organoleptic results. This technique is perfectly suited to dishes like fish, red meats, white meats and vegetables.